GIS casing

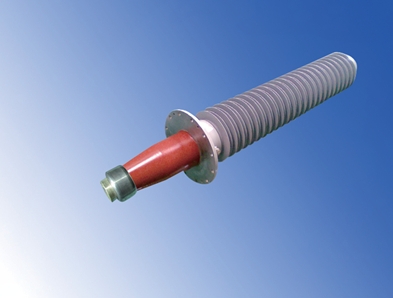

40.5-363kV FRP Capacitive GIS Bushing

FRP capacitive GIS bushing is applicable for direct connection between outdoor equipment and GIS. The bushing can be installed in any direction, which can be designed subject to user��s requirements.

In the power system, for the outgoing bushing operated in GIS substation, the outdoor part is SF6-filled type porcelain bushing. Pressure of internal gas reduces because of gas leakage during service, which results in disabled insulation and bushing explosion. In recent years, more and more compound hollow insulators are used, instead of porcelain bushing. Although the explosion risk is prevented, lots of work for supervision and maintenance shall be done, because gas leakage problem still exists. In addition, the gas will be concentrated (liquefy lower than -40��), which will get the insulating performance degraded when ambient temperature is pretty low, because the performance of SF6 gas in GIS outgoing bushing compartment is impacted from pressure. Thus, such kind of bushing shall not be adopted, if under pretty low ambient temperature.

The FRP capacitive GIS bushing developed by us is a kind of purely dry FRP capacitive GIS bushing, which uses independently developed new materials and production workmanships, with reference of design concept of same kind of products abroad. In addition to GB/T4109-2008, IEC60137Ed.6.0,MOD and other latest standards satisfied, the product possesses the obvious advantages as follows:

a. The product is oil-free, porcelain-free, and gas-free solid, without filler and leakage, having great moisture-proof performance, and no maintenance is required;

b. With a large designed insulation margin, semi-conductor capacitive panel furthest enhances the discharge inception voltage, and there is no partial discharge during service;

c. The anti-flaming insulation materials have stable electrical performance, without decomposition and risk of burning and exploding;

d. The product has compact structure, small sizes and light weight, which is easy to be transported and can be installed in any direction;

e. The fiberglass has the winding operation improved, and the mechanics layer design optimized, with high anti-bending strength and high mechanical strength, which is also reliable when serving at severe earthquake areas;

f. With perfect high and low temperature resistance performance, it used to be applied into electrostatic dust collector (+135��) and super-conduction cable connector (+90�� at one end, and -200�� at the other end);

g. Silicon rubber compound coating has an excellent anti-pollution flashover performance. It is self-cleaned, and can be used at heavy pollution area;

h. It possesses a long working life, with low cost against long-term service.

i. It has a short processing cycle, which can be specially designed according to user��s requirements.